Resistance welding is a process in which a contact resistance is generated when a current is passed through a workpiece, and welding is performed under external pressure. An electrode for holding a workpiece to be welded, passing a required current and transmitting an external pressure is called a resistance welding electrode. The tungsten-copper resistance welding electrode has good electrical conductivity, high temperature hardness and strength, and does not chemically react or adhere to the material to be welded.

More details of tungsten copper electrode, please visit http://www.tungsten-copper.com/tungsten-copper-electrode.html

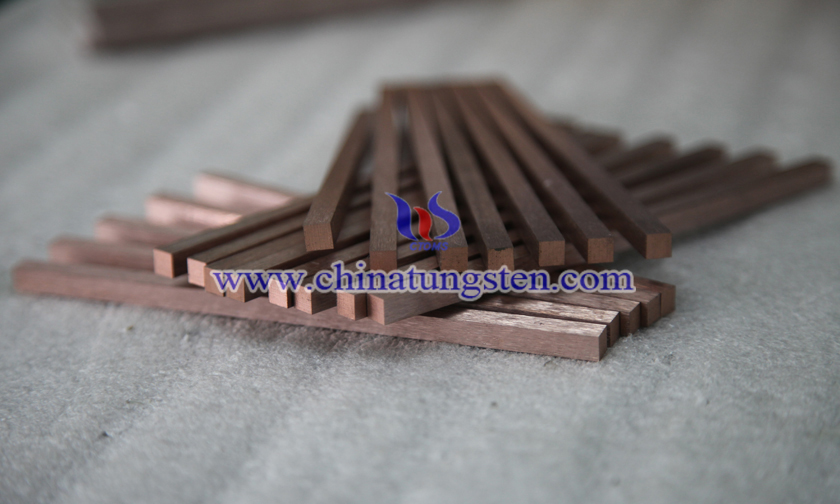

Tungsten Copper Electrode Picture

Tungsten copper alloy combines the advantages of tungsten and copper, high temperature resistance, arc ablation resistance, high strength, large specific gravity, good electrical and thermal conductivity, easy cutting, and has the characteristics of sweating, etc. Due to the high hardness of tungsten, High melting point and anti-adhesion characteristics, often used for projection welding and butt-welding electrodes with certain wear resistance and high temperature resistance.