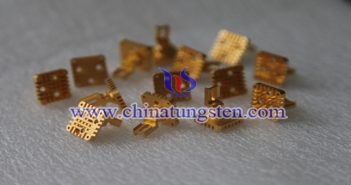

Tungsten copper W70 rod is composed of 70% W and 30% Cu so that it is harder than W50 and W60 rods. Its density is up to 12.75g/cm3, hardness reaches more than HB140, and conductivity is 47%IACS, softening temperature is ≥900℃ and the bending strength is 790. More details of W70 tungsten copper rod please visit http://www.tungsten-copper.com/tungsten-copper-rod-W70.html W70 tungsten copper rod pictureTungsten copper W70 rod belongs to refractory metal and has excellent mechanical strength and anti-arc ablation capability so that…