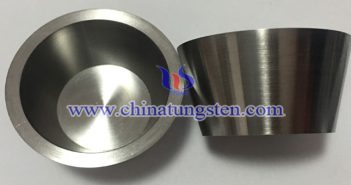

Spinning tungsten crucible means the tungsten crucible is produced by spinning process, with high purity above 99.95%, density of 18.5-19.0g/cm3 and outer diameter of 50-300mm. Spinning tungsten crucible has the characteristics of good quality, nice tensile strength, high hardness and high density, but it is difficult to operate as the hot rolling process and the spinning process are complex. Producing Process of Spinning Tungsten Crucible The tungsten sintered compact is prepared by powder metallurgy method, and is hot-rolled into thin…